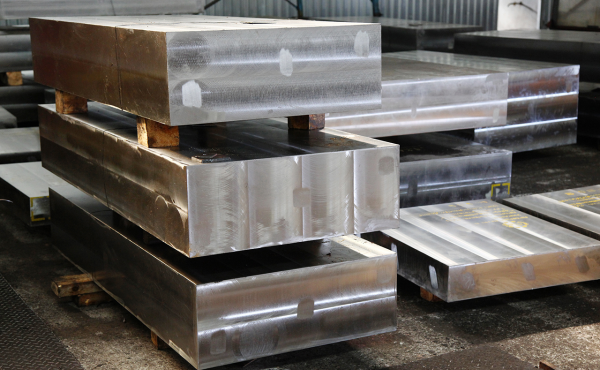

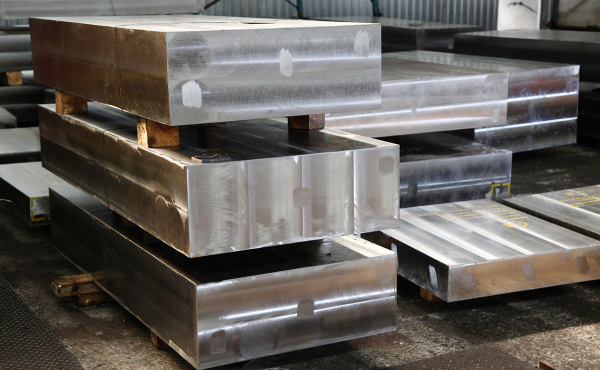

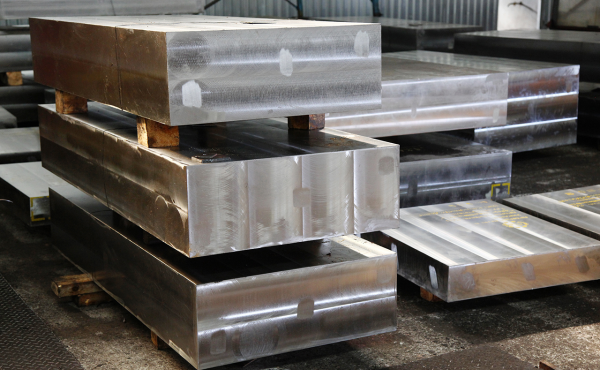

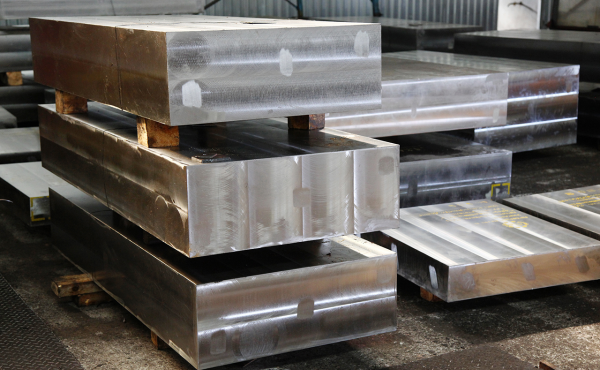

Our Products

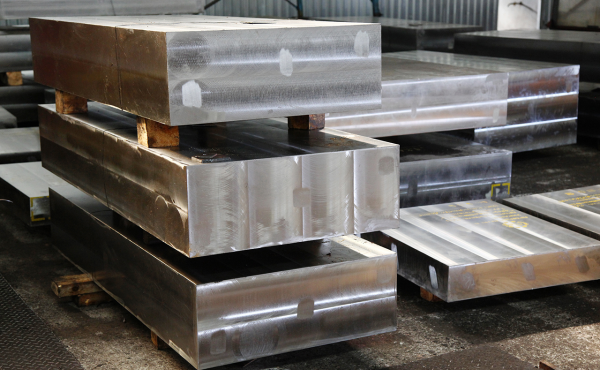

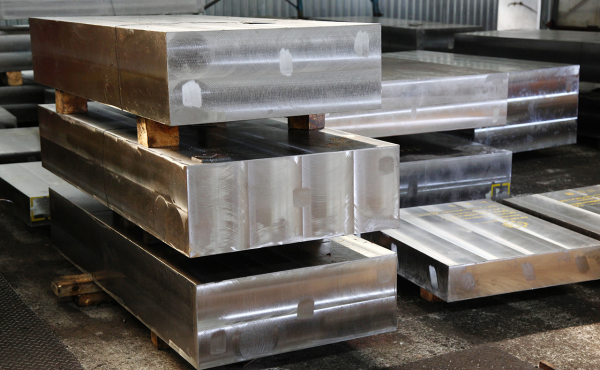

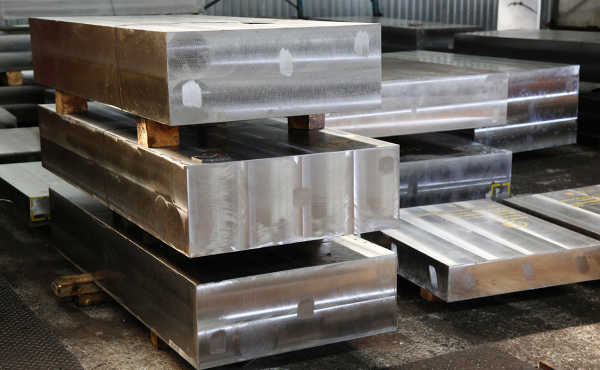

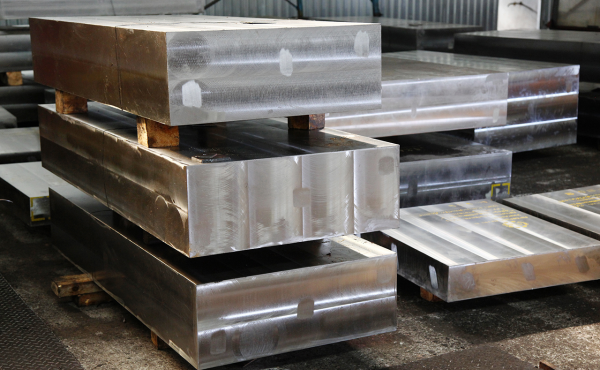

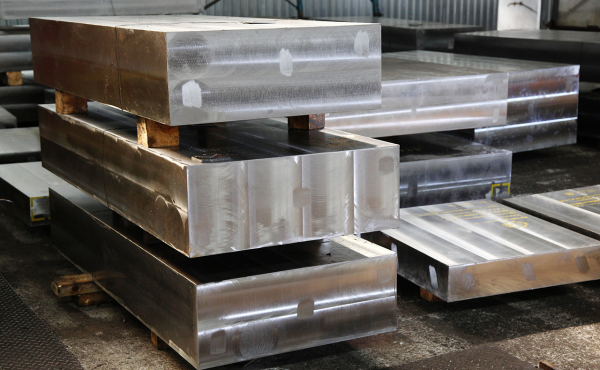

Cold Work Tool Steels

General Information It is an alloyed tool steel group suitable for working below 200°C in terms of usage temperature. The primary features expected from these materials are high hardness and wear resistance after heat treatment, as well as high resistance to impacts at this hardness. Usage Areas of Cold Work Tool Steels • Cutting tools, • Precision hole punch punches, • Scraping, scraping and breaking blades, • Drawing and embossing tools, • Deep drawing and plastering tools, • Paper and plastic cutting blades, • Sinter and pressing tools, • Wood saws, machine knives, • Drills, cutters, jaws, rollers, gear sets Features Expected from Cold Work Tool Steels • Clean and homogeneous micro structure, • High hardness and high wear resistance, • High fatigue strength, • High toughness

C 45W Delivery Method : Normalized, annealed 180-220HB Areas of Use: It is an unalloyed cold w...

X155CrMoV12-1 / AISI: D2 Delivery Method : Normalized, annealed 180-220HB Areas of Usage: It...

90MnCrV8 / AISI: O2 Delivery Method : Normalized, annealed 180-220HB Areas of Use: It is a col...

X45NiCrMo4 / AISI: 6 F 7 Delivery Method : Normalized, annealed 180-220HB Areas of Use: It is ...

60WCrV7 / AISI: S1 Delivery Method : Normalized, annealed 180-220HB Areas of Usage: It is ...

X100CrMoV5-1 / AISI: A2 Delivery Method : Normalized, annealed 180-220HB Areas of Use: It is a...

X210CrW12 / AISI: D6 Delivery Method : Normalized, annealed 180-220HB Areas of Use: It is a ...

X165CrMoV12 Delivery Method : Normalized, annealed 180-220HB Areas of Usage : It is a cold...