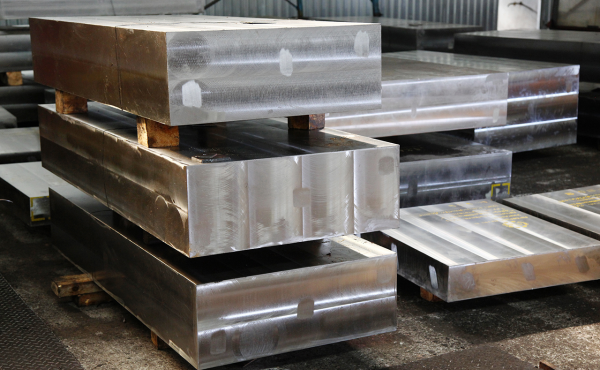

Our Products

Plastic Mold Steels

General Information It is an alloyed tool steel group that is produced for shaping all kinds of plastic raw materials with various methods, is resistant to abrasive plastics, can offer very high pressure and high polishability. In addition to being used for printing many plastic raw material-based products, it is also used in the mold holders of some metal injection molds. Plastic Mold Steels, which are used in the shaping of plastic-based raw materials, are a steel group that has a significant usage area in today's manufacturing and mold sector. It is used in many other fields, especially in the white goods industry, various household appliances, the construction industry, electrical-electronic parts and the automotive supply industry. Plastic mold steels are generally supplied to users in the form of heat treatment hardening. This has significant advantages for users. In fact, the heat treatment facilities required to obtain the appropriate steel internal structure and the desired hardness values are fully available in Özel and all necessary conditions are met. In addition, taking into account all the demands of the customers, the special conditions required by the process are provided. In short, the technological expectations shaped in line with customer demands are met by Özel, contributing to the technological development of the plastic mold industry. Some of the SPECIAL plastic mold steel grades that we recommend to be preferred according to the properties of the plastic material used; • 1.2311 ISO-BM quality steel for ABS molds up to 400 mm thick, • 1.2738 mod with high polishing ability, produced in 1.2738 ISO BM quality steel or higher hardness for mold manufacturing used for ABS and plastic materials that do not contain additives larger than 400 mm. THRUHARD SUPREME (HH) (310-355 HB ) • 1.2312 plastic mold steel with a relatively high sulfur content can be used in mold production where easy machinability is required. This steel can be used especially in mold parts that do not require high strength or mold parts where chrome plating and gloss properties are not required. • We have 1.2711 ISO-B and 1.2767 quality steels for molds with 310-355 HB hardness values, high Tensile Strength and good polishing quality. • 1.2316 mod ISO-B steel has been developed for forming plastic materials that cause high chemical erosion such as PVC and Aminoplast. In processes where high corrosion and stainless properties are required, 1.2316 steel can be used by hardening up to hardness values of 265-310 HB or 52 HRC when needed. Features Expected from Plastic Mold Steels • Clean and homogeneous micro structure, • Easy to process (including pre-hardened materials), • High abrasion resistance, • Resistance to high pressure of plastic raw material during operation, • Very good polishability, • High corrosion resistance, SPECIAL Tool Steels of which we are the Authorized Dealer in Türkiye as PINAR METAL; For all plastic materials such as Thermoplast, Duroplast, Elastomer and fiber-reinforced laminate, we offer Plastic Mold Steels in any desired size to Manufacturers and Manufacturers with SPECIAL quality and difference.

40CrMnMoS 8-6 / AISI: P20+S Delivery Type : Hardened and tempered 280-325 HB Areas of Use: It ca...

X33CrS16 / AISI: 420 FM Delivery Type : Hardened and tempered 280-325 HB Areas of Usage: I...

40CrMnNiMo 8-6 -4/AISI: P20+Ni Teslimat Şekli : Sertleştirilmiş ve menevişlenmiş 280-325 HB Ku...

1.2738 mod TS Delivery form : Hardened and tempered 280-325 HB 1.2738 mod TS (HH)* Delivery f...

40CrMnMo7/AISI: P20 Delivery Type : Hardened and tempered 280-325 HB Areas of Usage: It is used ...

X42Cr13 / AISI: 420 SS Delivery Method : Normalized, annealed 180-220HB Areas of Use: It i...

X36CrMo17 Delivery Type : Hardened and tempered 300-330 HB Areas of Usage: It is a stainle...